DPL was pleased to host Mr. Zhang Wei, CEO of Xiamen Node Technology Group Co.,…

How Industry 4.0 Technologies Can Impact Your Business

The demand for Industry 4.0 technologies is on the rise. In fact, the global market for these technologies is expected to reach $214 billion in 2023.

So, if you thought that Industry 4.0 and its tech are just another trend, here’s news for you. They’re here to stay.

“What is Industry 4.0?”

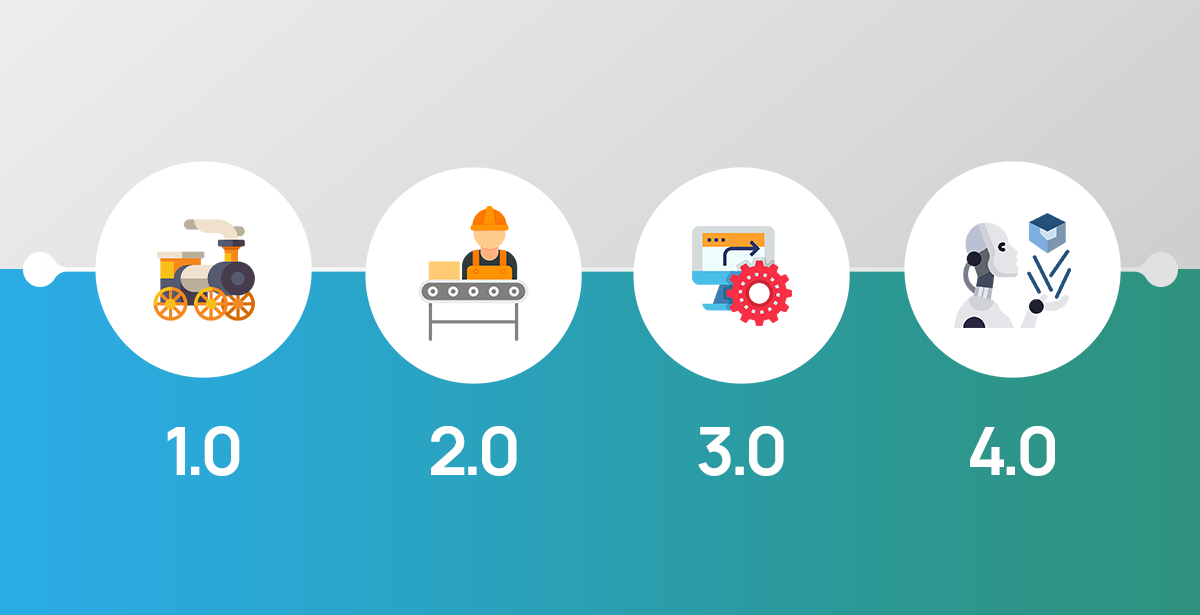

There’s an ongoing debate on the definition of Industry 4.0 as its boundaries aren’t fully defined. However, most agree that it’s the amalgamation of the previous eras –

- Industry 1.0, an era which ushered the use of steam and mechanization in production

- Industry 2.0, a revolution that was brought on with the discovery of electricity and the use of assembly lines in production

- Industry 3.0, the beginning of partial automation by using computers

However, 4.0 optimizes the computerization of 3.0 the most. Computers are connected and communicate to make decisions without involving humans. The use of the Internet of Things (IoT), cyber-physical systems, etc. further make Industry 4.0 a possibility.

Another way to define this is using Professor Klaus Schwab’s text from The Fourth Industrial Revolution. According to him, Industry 4.0 covers –

“New technologies that combine the physical, digital and biological worlds, impacting all disciplines, economies and industries. These technologies have great potential to continue to connect billions more people to the web and drastically improve the efficiency of business and organizations.”

And if you’re still curious about the definition:

“What Industry 4.0 Technologies Can I Use in My Business?”

Industry 4.0 technologies are truly what make this revolution possible. They promote connectivity, automation, and optimization, driving the digital transformation unique to this era.

In addition to big data analytics, 3D printing, autonomous machinery, digital twins, and cybersecurity, consider the following.

The Internet of Things (IoT)

The Internet of Things (IoT) comprises a network of physical objects that are connected to the internet.

Fitted with sensors, software, and other technologies, these ‘things’ can exchange real time data with other connected devices. The latter can be combined with automated systems that gather data to assist with tasks or help improve processes.

IoT is one of the more prominent Industry 4.0 technologies because of its widespread use and impact on daily lives. Especially in smart homes, which are currently crossing 200 million in number.

Other contributions of IoT to Industry 4.0 including making tech function smoother and increasing the performance of manufacturing.

The Industrial Internet of Things (IIoT)

IIoT entails the use of smart sensors and actuators to support manufacturing and industrial processes.

Basically, this technology captures and analyzes data from industrial machines in real time. Something humans can’t do. It then communicates these findings quickly to ensure faster, more accurate business decisions.

With this data, businesses can optimize their operations. In particular, processes and maintenance operations will be optimized. This, in turn, can create new revenue streams and improve productivity and quality without adding pressure on resources.

Cyber-Physical Systems (CPS)

Another interesting Industry 4.0 technology, CPS integrates computation, networking, and physical processes to engage humans like never before. It’s related to sensor networks that use computational intelligence to function (e.g., robotics).

CPS is mainly found in agriculture, transport, healthcare, energy, and home automation. For instance, wearable sensors and non-intrusive environmental monitors can be used to detect changes to patients’ vital signs and ensure prompt emergency response.

On this list, CPS is relatively in its initial stages. Challenges such as privacy and interoperability still prevent it from becoming as prevalent as other Industry 4.0 technologies. However, it won’t be long until this tech’s applications take place more often.

Smart Manufacturing

Like CPS, smart manufacturing is a disruptive technology that’s quickly making strides across industry verticals.

Smart manufacturing is a broad concept; it covers concepts such as digital manufacturing and cyber manufacturing. It entails the use of emerging and advanced technologies to enhance the efficiency of traditional manufacturing processes.

As the term began gaining momentum in the mid-2000s, this technology is still new. However, it has proven to be useful for asset management and quality assurance. That too for small and medium sized companies as well as larger ones.

Smart Factories

As you probably have guessed, a smart factory is a digitized facility that uses connected devices, machinery, and systems to gather and share data. That way, decisionmakers can make informed decisions, improve processes, and address possible issues.

Smart factories rely on smart manufacturing practices powered by technologies like artificial intelligence (AI), big data analytics, and IIoT. That’s why of other Industry 4.0 technologies, they’re more common.

In fact, by 2019, PwC reported that half of the manufacturers it surveyed were in the initial stages of transitioning to smart factories. By 2020, the firm predicted 73% would increase investments in this technology. Therefore, businesses considering transitioning to smart factories should do so quickly.

Cloud Computing

Cloud computing is probably one of the Industry 4.0 technologies that most are well aware of. It transforms IT infrastructure into a utility that provides in-demand access to computing resources without installing them on a device.

These resources – including applications, servers, development tools, and more – are hosted at a remote data center. A cloud services provider ensures these resources are available for a subscription fee or bills you according to usage.

Cloud computing is another key player in the development of the Fourth Industrial Revolution. It allows businesses to adapt quicker to new technologies and the opportunities 4IR has to offer. However, you should prioritize security vulnerabilities such as data protection to avoid this technology’s challenges.

Cognitive Computing

Cognitive computing combines machine learning, data mining, neural networks, and visual recognition to mimic human behavior and reasoning. The technology interacts with humans naturally, learning over time and reasoning with purpose.

This is a game changer for many businesses as it understands language, recognizes objects/people/text/voice, and interacts with people and machines alike.

However, it doesn’t possess the emotions and spiritual characteristics humans have. Therefore, it ideally should be used with humans, rather than replacing them altogether. That way, people can do more skillful jobs in the future.

Artificial Intelligence

Last, but not the least, is artificial intelligence.

By definition, artificial intelligence is the branch of computer science that aims to replicate or stimulate human intelligence in machinery. With advancements in machine learning and deep learning, it may not be long before machines gain ‘intelligence’.

Fun fact – this is probably one of the oldest Industry 4.0 technologies. Its vision and fundamental goal go all the way back to the 1950s.

However, AI is more useful now considering the explosion of data. With every human-created 1.7 MB of new information per second, AI is showing its true potential.

“So How Can Industry 4.0 Technologies Benefit My Organization?”

Now that you’ve become acquainted with Industry 4.0 technologies, here’s how they can transform your business.

Enhanced Productivity

This is probably the first benefit you’ll notice upon implementing 4IR technologies. This is possible as the options above save costs, increase profitability, prevent errors and delays, and much more.

Real-Time Data

Your success in the current economy relies on data and information. This data spans all your operations and goes beyond the delivery of a product to the end customer.

One of the biggest benefits of real-time data is allowing businesses to quickly customer expectations. Especially since speed isn’t just a competitive advantage; it’s a demand customers have from businesses they deal with.

Higher Business Continuity

Advanced maintenance and monitoring allow you to save the time, money, and effort otherwise wasted when industrial assets break down. As a result, you won’t need to worry about production being affected or dealing with unhappy customers.

Most importantly, you won’t have to worry about damage to your reputation and cancelled orders. Therefore, your business continuity won’t become your worst nightmare.

Top Quality

With Industry 4.0 technologies, you won’t need to compromise on quality to achieve speed.

Automation, combined with the components of CPS and/or IoT, allows you to monitor quality aspects in real-time. The use of cobots (collaborative robots that collaborate with humans) further reduces errors.

Better Workplaces

4IR technologies have the potential to improve working conditions. For example, they can control real-time temperature in warehouses and detect gasses/radiation in factories. As a result, these technologies have the potential to improve work conditions and enhance safety.

They can further ensure sustainability through initiatives like clean air. And this will help achieve one of the main goals of implementing Industry 4.0.

Improved Agility

Agility, scalability, and flexibility – these are three great benefits you can expect from bringing 4IR tech into your organization. Adjustments that you otherwise believed to be less predictable will become more visible and, therefore, easier to handle.

New Revenue Streams

These technologies have the power to unleash innovative capabilities within your organization. From processes to customer services, and all the way to experiences – everything will be transformed.

Therefore, you can expect generous additions to your bottom line as you explore new services and offerings with this tech.

We’re Here to Help You Get the Most from Industry 4.0 Technologies

As experts on digital transformation and 4IR tech, DPL’s consultants can help you meet your business goals. We’re also the right people to create custom solutions that allow you to reap the benefits you read about and more.

So, get in touch with us using the form below and let’s get your business up to date with Industry 4.0.